Application:

It is suitable

for automatic packing and packing of oat, rice roll, lollipop, crisp candy and

other cylindrical, puffed food and other similar stick-shaped items. It can be

equipped with large-scale production lines to realize seamless connection and

automated production.

Specification:

1. Adopting

international high-end technology, full-automatic computer touch screen

control, 9-axis servo motor device system, you can easily and quickly adjust

packaging of various sizes.

2. Multi-zone

temperature control device, which can be set freely on the touch screen,

excellent packaging and high-quality seals to ensure the product quality of the

packaging;

3. Configure

high-speed automatic film connection function to achieve the highest power

ratio of automatic film change without stopping;

4. There is an

automatic detection and feeding system to truly achieve no empty packages, and

the packaging rate reaches 100%;

5.The obliquely

arranged sorting tray uses the principle of the height difference of the

sorting tray to divide, sort, and feed. The packaging speed can be

automatically adjusted according to the amount of materials to reduce the

friction and waste of the packaging.

6. It can be

directly connected to the production line to automate the whole process of

material distribution, sorting, feeding, filling and sealing, greatly reducing

labor costs and improving production efficiency;

7. Automatically

display alarms for mechanical failures to facilitate operation, maintenance and

repair.

8. Can be

customized according to customer needs.

Technical

parameters:

Packaging speed:

100-600 capsuTles / min

Forming bag

length: 70-180mm

Packaging

specifications

Length: 30-125mm

Width: 15-40 mm

Thickness:

10-30mm

Packaging film

materials: OPP, CPP, PET, aluminized film, aluminum-plastic film and other

single or multiple layers of heat and cold sealing materials

Voltage: 380V

Total power:

7.5KW

Weight: 1680KG

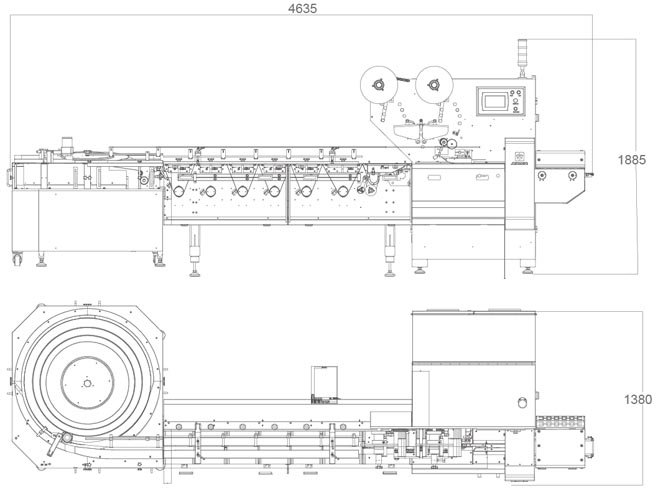

Dimensions: 4635

* 1380 * 1885mm

|